High Performance Polymer FRP Solutions

High Performance Polymer FRP Solutions. Holding It Together:

Isoplast® 101 LGF40 Engineered Thermoplastic

Today we are going to take a closer look at a good all-around material for industrial applications. Isoplast® 101 LGF40 is a fiberglass reinforced polymer (FRP) and is one of the strongest, most durable building materials available in the marketplace today. There are a variety of names that this material is commonly known by, including Complēt® LGF40-TPU, Celstran® LFRT, Fiberfast™, and Fiberglass.

In comparison to commonly considered industrial materials like wood, steel, and aluminum, LGF40-TPU doesn’t rust, warp, or corrode, making it environmentally sound. LGF40-TPU is also a fraction of the weight for efficient transportation and installation.

It’s a different way to approach your design challenge and makes Isoplast LGF40-TPU an ideal candidate for mechanical connections that require a higher degree of corrosion resistance in demanding environments. They can even be submerged in a marine environment for an extended period with no effect.

We incorporate the highest quality material to provide non-conductive components that offer superior chemical resistance, higher strength, and ultraviolet protection.

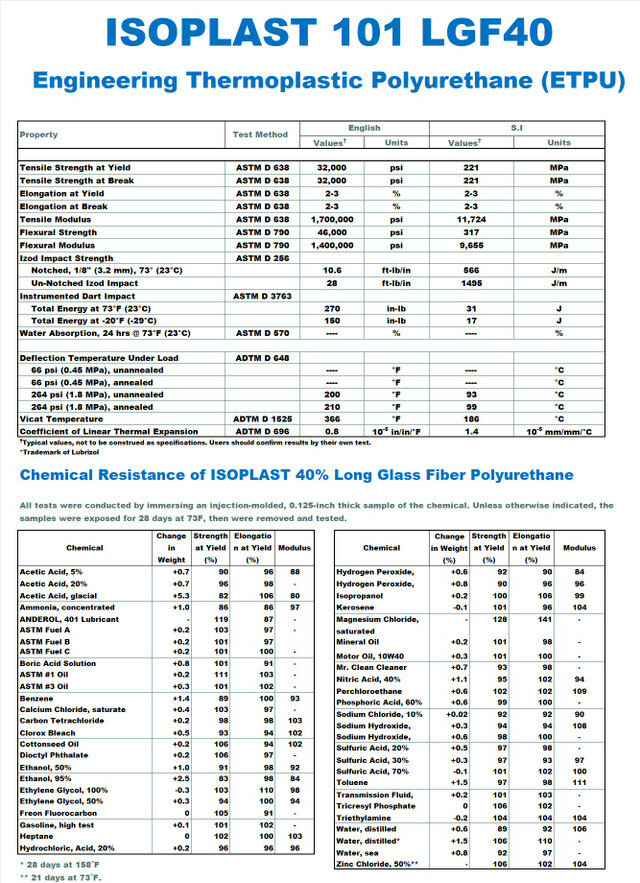

Isoplast® 101 LGF40 Engineered Thermoplastics (ETPs) are designed for rigid polymer requirements due to their high tensile strength and impact resistance. The resin that we utilize to produce our components is a premium long fiber reinforced thermoplastic (LFRT) that unites long fiber reinforcements with the Thermoplastic Polyurethane (TPU) resins for a combination of mechanical properties, impact, creep resistance, and low warpage that yields higher physical properties than the traditional production process.

TPU is considered in a variety of demanding applications because it combines the toughness and dimensional stability that you expect from amorphous resins with the chemical resistance of crystalline materials. Let’s take a closer look at Isoplast® 101 LGF40 below:

We are a leading supplier to a variety of industries, including RF Transparent products designers that integrate wireless infrastructure into the look and character of the end user’s environment. Our components are used to manufacture a variety of unique cabinet enclosures in a full array of architecturally concealed sites, including cacti, boulders, and trees.

Due to the physical properties and chemical resistance present in the LGF40-TPU material, it finds success in a variety of applications, including the following:

- Aquaculture Pens

- Flue gas desulphurization plant

- Onshore / offshore engineering

- Chemical plants

- Hydraulic engineering, sewage treatment plants, desalination of seawater

- Transformers, dry-type and oil-immersed

- Generators

- Switchgears

- Instrument construction, High-frequency Systems

- Traffic engineering

- Refrigeration and air conditioning

- Cable trays

- Electrostatic powder coating

- Electroplating plants

- RF Transparent Site Concealment

- Wireless Networking Technology

We offer a variety of injection-molded fasteners in the 101 LGF40 TPU in both a natural (off-white) or gray, with a variety of solutions available off the shelf or with quick turnaround. See below an example of our injection-molded flange nuts that we offer to our partners:

Contact us today and let us know how we can help!