Chemical Resistance Plastics

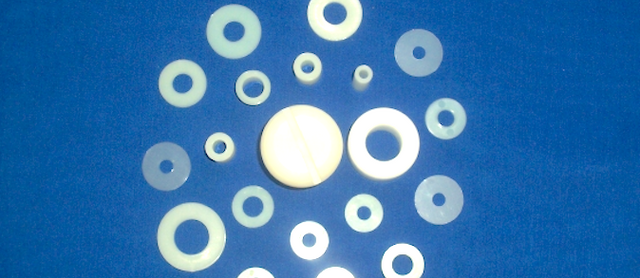

Chemical-safe plastics are regularly called for in numerous building applications such as clasp-like screws and hex nuts and numerous other custom parts. Not all plastics will hold up well in extraordinary situations. But there are certain plastics that tend to hold up well in chemically cruel situations. These include the semiconductor preparing hardware, therapeutic, nourishment handling, and chemical handling businesses.

Here is a list of four commonly utilized chemically safe plastics:

Kynar® resins have amazing resistance to temperature, cruel chemicals, and atomic radiation. They are utilized within the control, renewable energies, and chemical preparing businesses. Also, it is utilized within the pharmaceutical, therapeutic, nourishment & refreshment, and semiconductor businesses for its tall purity.

PVDF is accessible in multiple shapes. PVDF is additionally one of the foremost known chemical-safe plastics within the mining, plating, and metal arrangement businesses. This ubiquity is due to PVDF’s resistance to hot acids in a wide range of corrosive qualities. PVDF is additionally utilized within the auto and engineering markets for its chemical resistance and amazing resistance to UV corruption and extraordinary climate and conditions. Look shows amazing mechanical and warm properties, as well as crawl resistance at tall temperatures, exceptionally low combustibility, hydrolysis resistance, and radiation resistance. These properties make Look a favored item within the aviation, car, telephonic, and chemical handling businesses. Look is utilized for wear and load-bearing applications such as valve seats, pump gears, and compressor valve plates.

PVC: Due to its wide utilization as indoor and in-ground wastewater channeling, thousands and thousands of tons of PVC are delivered each year, making PVC the third most delivered plastic. PVC is utilized in development as it’s more viable than conventional materials such as copper, press, or wood. PVC can be made milder and more flexible with the expansion of plasticizers. In this shape, it is utilized in clothing, floor coverings, and furniture. PVC’s status as a chemical-safe plastic makes it a perfect fabric for window and entryway outlines, protection of electric cables, open-air signs, sports gear, therapeutic tubing, for floors, greenhouses, and open-air play areas. For those of you with an eye for trivia, a fun truth is that one of PVC’s early employments was in vinyl records. PVC has great adaptability, is fire retardant, and has great warm soundness, a tall sparkle, and no lead substance. Polyvinylchloride molding materials can be expelled, infusion molded, compression molded, and blow molded to create a colossal assortment of items.

CPVC gum is made by the chlorination of PVC tar and is utilized for the most part to deliver channeling. CPVC offers numerous properties with PVC, counting moisture conductivity and amazing erosion resistance at room temperatures. The extra chlorine in its structure too makes it more resistant to erosion than PVC. While PVC starts to mellow at temperatures over 140°F, CPVC is valuable to temperatures of 180°F. Like PVC, CPVC is fire-retardant. CPVC can be effortlessly worked. It can be utilized in hot water channels, chlorine channels, sulfuric corrosive channels, and high-pressure electric cable sheaths.