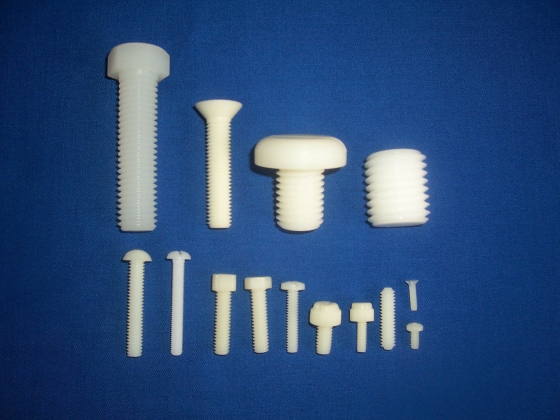

Nylon Plastic Fasteners -Why Consider?

Dec 6th 2023

Nylon is one of the most widely used plastics in the world, and all grades of nylon plastic fasteners maintain great strength and offer extremely good wear resistance. Also, it can withstand continuous contact with a variety of chemicals, alkalis, and dilute acids. Economically, Nylon is an excellent product.

Nylon Plastic Fasteners

For use in tools such as spudgers, nylon is available in glass-filled variants which increase structural and impact strength and rigidity. Its various properties also make it very useful as a material in additive manufacturing; specifically as a filament in consumer and professional grade fused deposition modeling 3D printers.

In which applications can you use Nylon Plastic Fasteners?

Nylon is often used used when high mechanical strength, great rigidity, and good stability under heat is required. It’s ideal for use in electrical and mechanical hardware as it reduces maintenance over other materials. Additionally, nylon is used in lieu of bronze, brass, aluminum, steel and other metals to reduce weight and noise from metal to metal contact. It is frequently used for machine screws, washers and stampings, gears and other low- to medium-stress components previously cast in metal such as ball bearing cages, appliances, and business machines.

Characteristics/Properties

The characteristic features of nylon include:

- Light weight (approximately ½ the weight of aluminum)

- Pleats and creases can be heat-set at higher temperatures

- Has a more compact molecular structure

- Includes better weathering properties and sunlight resistance

- Higher melting point:

463–624 K

190–350 °C

374–663 °F - Superior colorfastness (on the other hand, nylon is easy to dye, and more readily fades)

- Excellent abrasion resistance and resistances to organic solvents and gasoline

- Higher impact resistance

- A more rapid moisture absorption. Nylon parts are hygroscopic – (ability to hold water molecules drawn in from its surroundings). Therefore, when injection moulded, nylon plastic fasteners retain latent heat from the manufacturing process and continue to absorb moisture.

- Greater elasticity and elastic recovery

Summary

When choosing components and fasteners for manufacturing and production, it’s important to consider the application, the environment of the finished products and the characteristics of the materials available. Plastics, and especially some of the advanced composite materials, make a great choice for many applications and offer exceptional strength and resistance to wear.

Nylon is a very popular choice within a wide variety of plastic fasteners, but it’s not used in every application. If you have any questions on the properties of nylon plastic fasteners, or its use within your application, please do not hesitate to contact us. We’re here to help